As a manufacturer and distributor of high-quality units, such as scanners, computers, aircrafts or medical instruments, it’s crucial to retain your aftermarket. Light Sources now offers its global OEM specialty fluorescent lamp customers a sustainable and beneficial concept, which we have successfully marketed to our UV germicidal lamp clients. And we’ve done this for over 27 years with tremendous success. The customized and proprietary solutions are one of the many reasons why clients have described us as an organization where “customer commitment is second to none”.

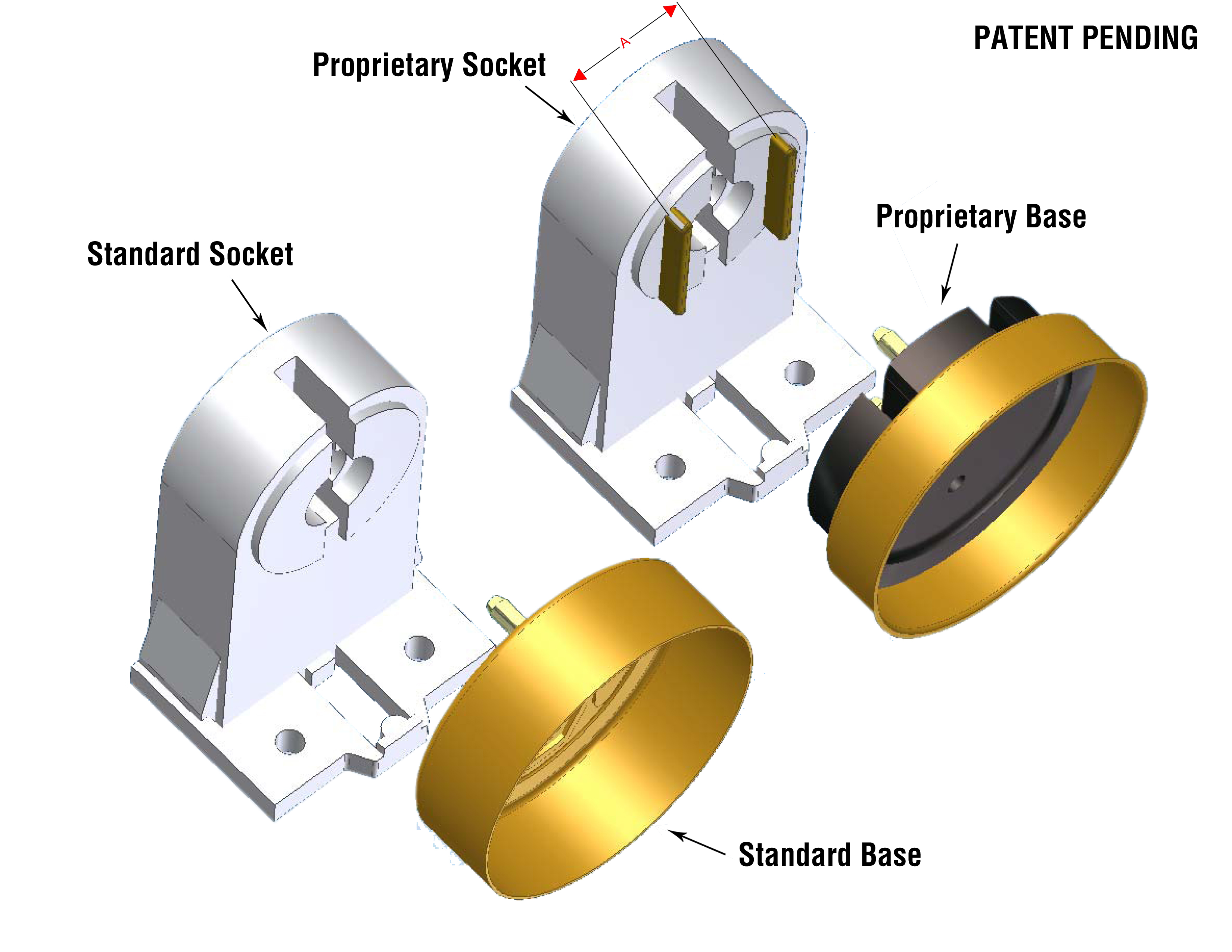

What we do is simple: We support equipment manufacturers like you to build, nurture and protect their aftermarket business. No, it has nothing to do with magic – we are a manufacturer just like you. However, by working with us, you not only can offer a branded line of high-performance fluorescent lamps in any lengths, any shape or in any proprietary phosphor blend. You can also benefit from a complete lamp range – from T5, T8, T6, T10 to T12 – with patented bases and sockets specifically designed for your quality units and your individual exclusive use.

So, what’s the point of completely customized and proprietary specialty fluorescent lamps? It goes back to offering your customers something no one else can!

Today, every manufacturer looks for proprietary uniqueness that will give them an edge in the market. In terms of your own systems or units, that differentiator can be the form factor of the unit, or the onboard features designed into the unit. You agree with us? Then check out the guaranteed benefits or simply consider it as your distinct advantage in an ever growing competitive industry.

Add value to the components and parts of your systems:

- Have components that match your corporate identity guidelines

- Choose any base/socket colors that will set your systems apart from competitors (all standard pantone colors available; premium colors upon request)

- Maintain and assure the performance of your tanning equipment

- Enjoy greater flexibility in your system designs

Base Types:

- No base – typically used for harness assemblies

- T5

- Medium Bi Pin

- RDC

- Custom ceramic

Ceramic end fittings – Both standard and special OEM design bases available. Caps provide excellent heat resistance and offer compatible TCE with respect to the lamp glass.

Convinced? Contact us today. We can design and provide rapid prototyping with bases/sockets within one week or less (3D model files .stp). Prototypes can be crucial in your preliminary system designs. They are highly valuable as first phase physical samples for determining dimensional compatibility between our lamps and your system.

How Long is a Base/Socket Design & Patenting Process?

It’s not as long as you would expect! We are not only very experienced with unique base designs, but also with the procedures of Patent & Trademark Offices. Your individual proprietary project can be nailed down within a couple of months. Click here for a sample project plan (may vary on a project-by-project basis).