Aperture & Reflector Lamps

Fluorescent reflector and aperture lamps are foremost designed to control the direction of the light output. Combined with an effective fixture design, controlling the inherently uniform lamp output along the length of the fluorescent tube is achieved. Although most aperture and reflectors are used in linear T12 (38.1mm) lamps, they can be designed into any lamp style from straight to bent lamp geometry and into lamp diameters as small as 3.0mm.

The LCD Lighting Difference

Our aperture and reflectors offer our OEM clients many benefits, including:

- Highly reflective internal reflectors and/or apertures for special task lighting.

- Provide the most useful control of light for the specific requirements of the application.

- An extensive array of design configurations. Outside glass diameters from 2.9mm to 38mm and lamp lengths up to 3048mm (120 inches).

- Cold-cathode or hot-cathode (rapid start, preheat or instant start) modes of operation.

- Dimmable or fixed current operation.

- Standard or custom configurations – straight, “U”, circular, or any custom shape.

- HCFL and CCFL technology

- Operating life of thousands of hours depending on driving current (amps).

- For use in all commercial and industrial environments

- LCD Lighting proprietary manufacturing process.

Reflector Lamp Design

Internal Lamp Reflectors are used to direct a portion of a 360° lamp output to increase the magnitude of the output in one direction. The reflector effectively re-directs the light from the sides and back of the fluorescent tube to the non-reflector area of the lamp coating. Many applications use this technology in conjunction with an external fixture (polished or metallic) which also acts as a reflector to direct the light energy to where it is needed the most. Common applications for this technology ares the flexo graphic, aquarium, scanning, vision markets and essentially, anywhere light distribution needs to be optimally distributed.

Internal Lamp Reflectors are used to direct a portion of a 360° lamp output to increase the magnitude of the output in one direction. The reflector effectively re-directs the light from the sides and back of the fluorescent tube to the non-reflector area of the lamp coating. Many applications use this technology in conjunction with an external fixture (polished or metallic) which also acts as a reflector to direct the light energy to where it is needed the most. Common applications for this technology ares the flexo graphic, aquarium, scanning, vision markets and essentially, anywhere light distribution needs to be optimally distributed.

Advantages of the internal reflector are that the light output is not affected by dust or dirt that can accumulate on the top of the lamp nor on existing external reflector housing. This internal reflector is not affected by the various environmental conditions. Reflector lamps can be used in smaller, less costly fixtures to improve light direction while keeping costs down.

Advantages of the internal reflector are that the light output is not affected by dust or dirt that can accumulate on the top of the lamp nor on existing external reflector housing. This internal reflector is not affected by the various environmental conditions. Reflector lamps can be used in smaller, less costly fixtures to improve light direction while keeping costs down.

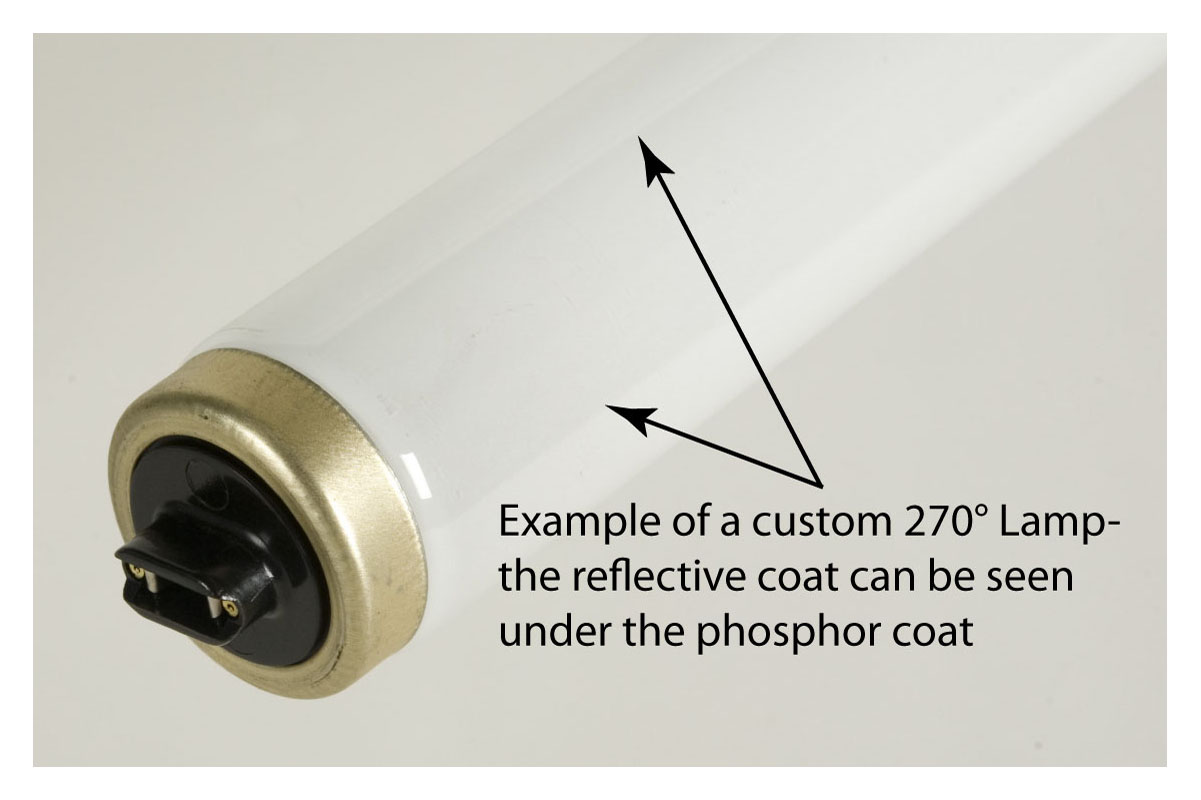

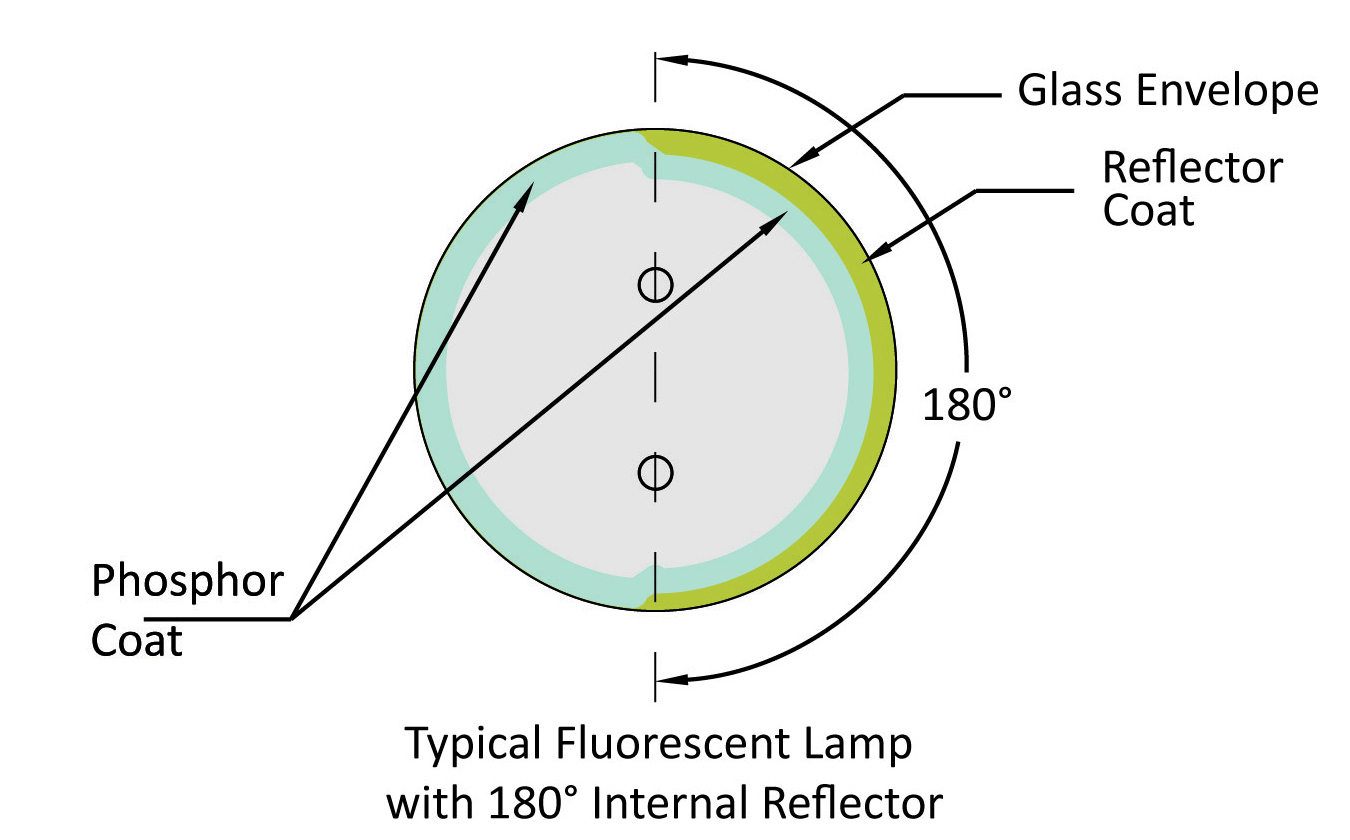

Reflector lamps are most commonly made with an internal reflective coating of 180° to 235° of the inside of the glass envelope. Other custom reflectors sizes can be specified and manufactured, but the most common internal reflector is 180°.

In this kind of lamp, the initial reflective layer is applied, covering half of the inside surface (circumference) of the lamp. The second layer is the phosphor layer- which coats the entire interior surface of the glass envelope. This reflective layer helps to direct the light to the opposite side of the lamp. This improvement in surface illumination by a reflector lamp when compared to a standard lamp is dependent on the fixture design and external environmental conditions, but generally provides 30% – 50% increase in light output striking the desired surface.

In this kind of lamp, the initial reflective layer is applied, covering half of the inside surface (circumference) of the lamp. The second layer is the phosphor layer- which coats the entire interior surface of the glass envelope. This reflective layer helps to direct the light to the opposite side of the lamp. This improvement in surface illumination by a reflector lamp when compared to a standard lamp is dependent on the fixture design and external environmental conditions, but generally provides 30% – 50% increase in light output striking the desired surface.

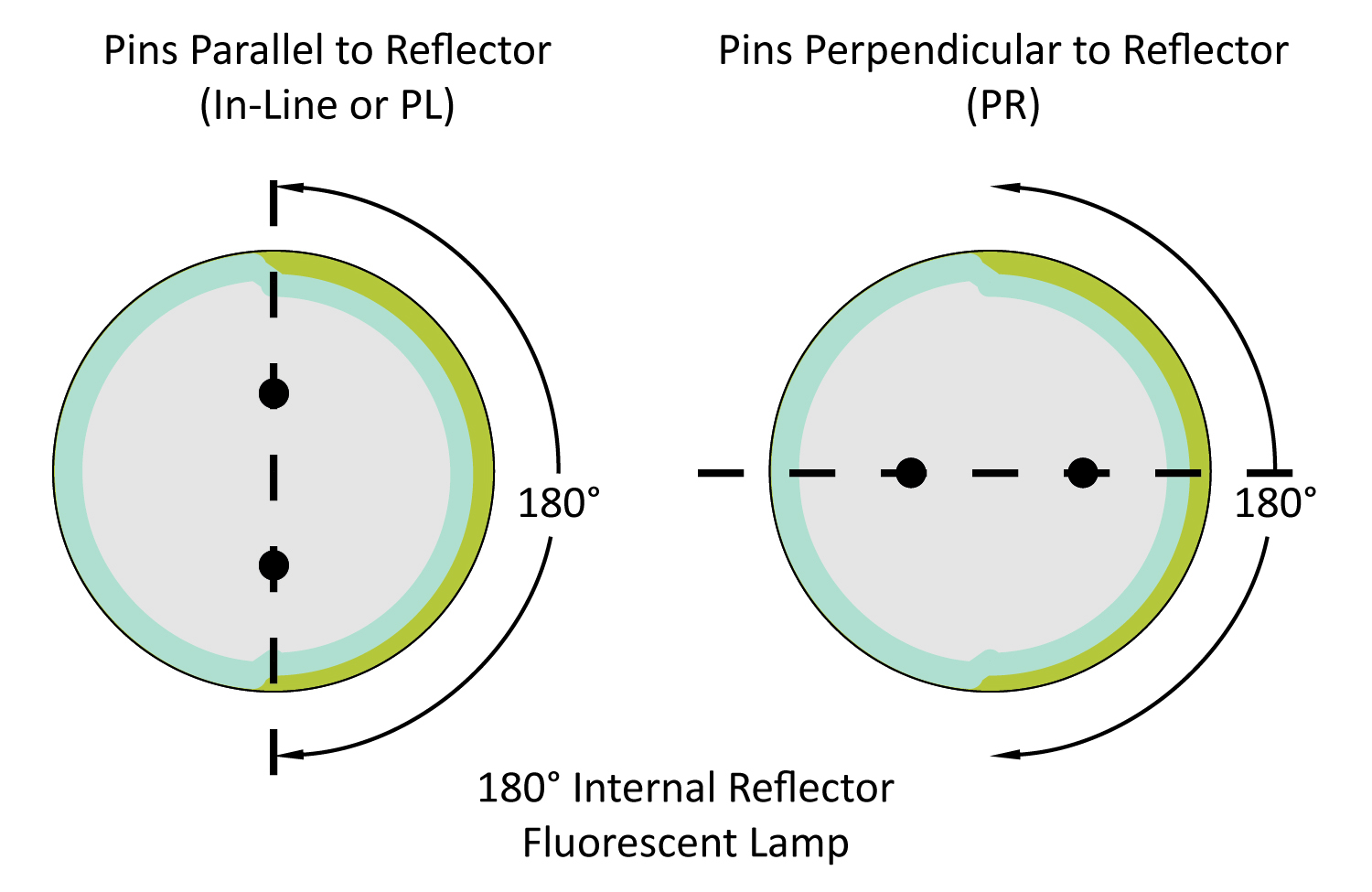

When ordering or even specifying a new lamp design with an internal reflector, the pin to reflector orientation must be considered. The two most common orientations are pins In-Line (parallel) and pins Perpendicular to the reflector. The pin orientation must be considered to assure that during installation, the lamp has the maximum output directed to the application surface.

Aperture Lamp Design

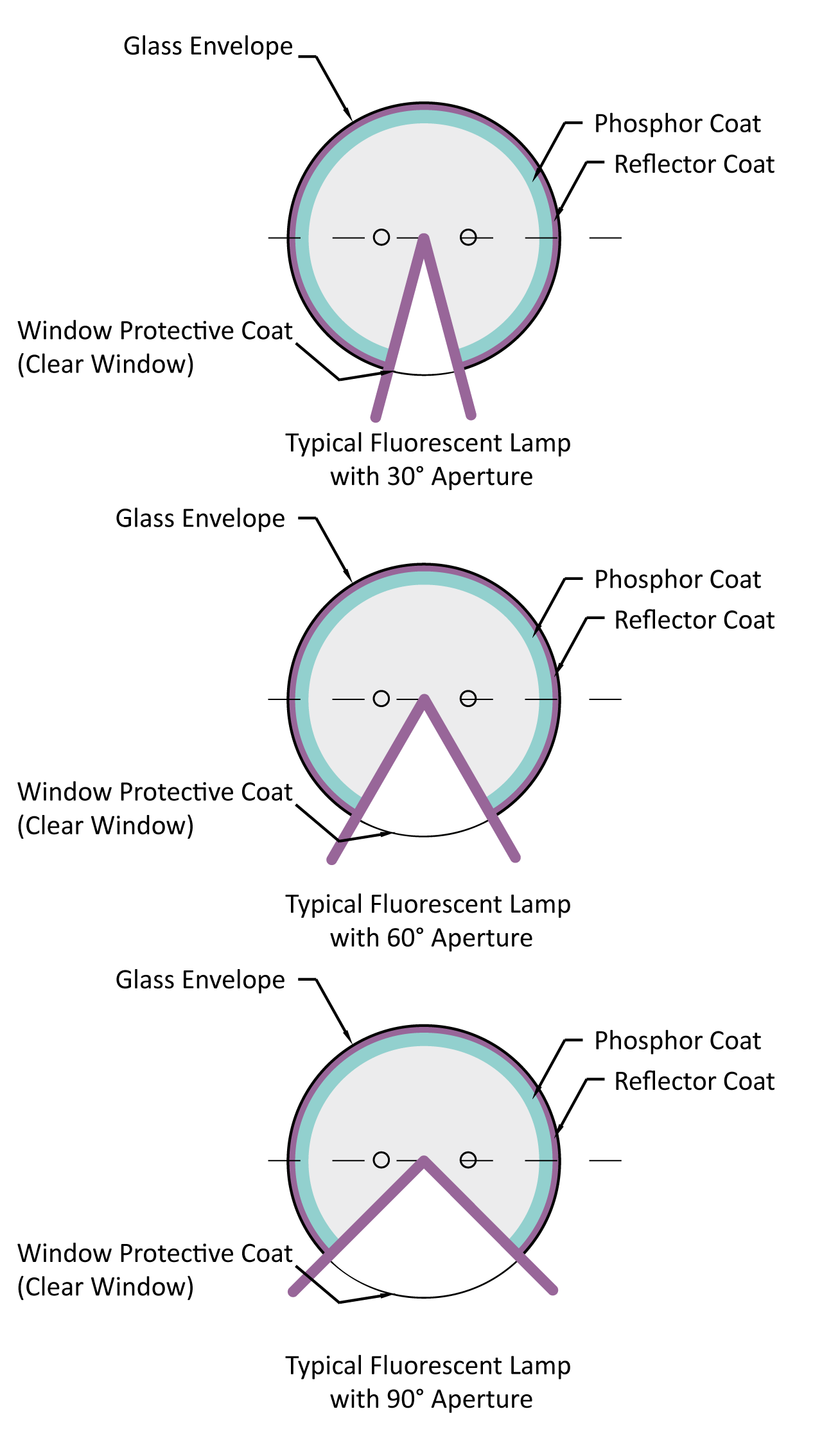

Aperture lamps are similar in construction to internal reflector fluorescent lamps except that the reflector covers a larger portion of the circumference and there is a clear window in the coating for the light to come through. This clear area does not contain any phosphor. This “aperture window” concentrates the light in one direction and provides higher intensity often expressed as brightness.

Aperture lamps are similar in construction to internal reflector fluorescent lamps except that the reflector covers a larger portion of the circumference and there is a clear window in the coating for the light to come through. This clear area does not contain any phosphor. This “aperture window” concentrates the light in one direction and provides higher intensity often expressed as brightness.

The clear aperture window is specified in degrees with the most commonly requested aperture windows being 30° and 60°. The size of the aperture is an important consideration with the light intensity being greatest at the aperture surface. The light intensity increases with decreasing aperture width. With the precision of LCD’s advanced lamp manufacturing technology, the aperture width can be specified as small as 2 millimeters wide.

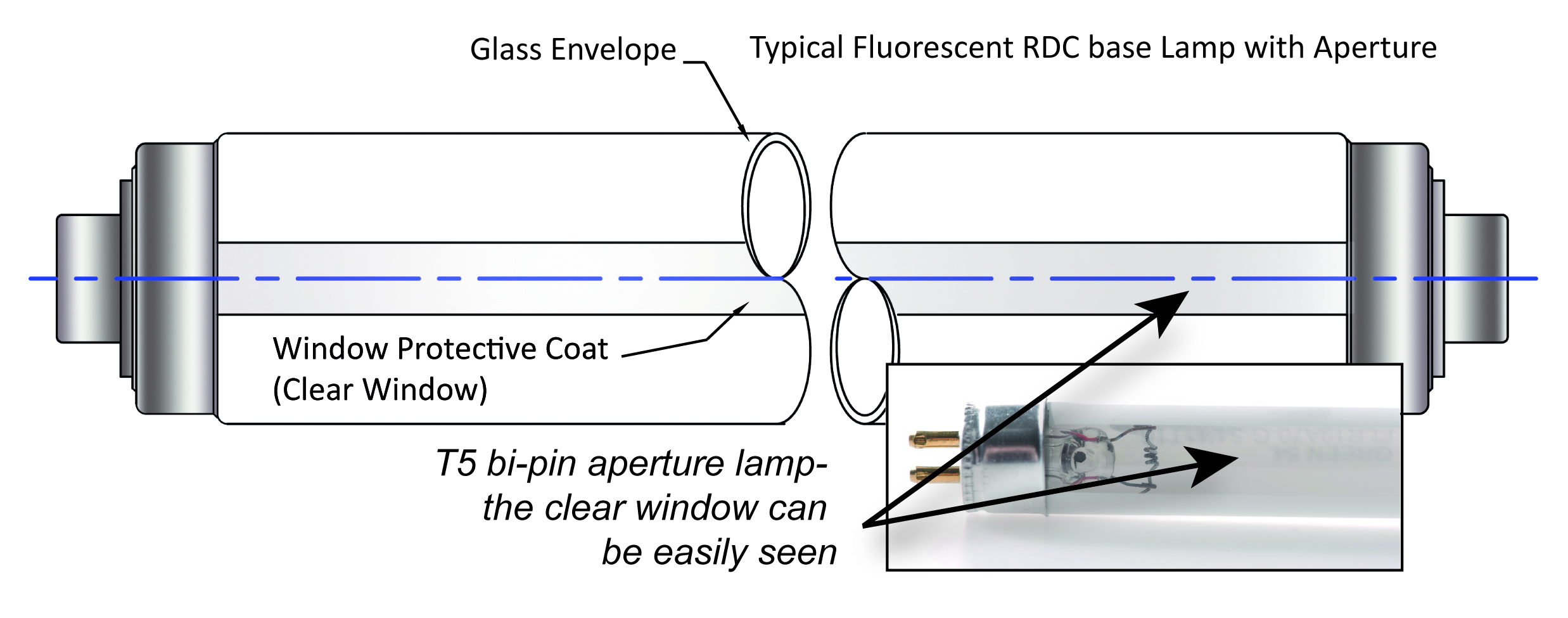

Aperture lamps can be made in all lengths (50 mm – 2,4 meters) and diameters (3.0 – 38.1mm) as well as containing any phosphor type. Aperture lamps with bi-pin or RDC bases can also be specified as

Aperture lamps can be made in all lengths (50 mm – 2,4 meters) and diameters (3.0 – 38.1mm) as well as containing any phosphor type. Aperture lamps with bi-pin or RDC bases can also be specified as

in-line (parallel) to the aperture as shown or perpendicular (rotated 90°) or any special orientation requested by the customer.

LCDL Lighting’s aperture lamps have been commonly used scanners, facsimile machines, copiers and other vision and inspection and imaging systems around the world. Aperture lamps are found in many quality and process control applications, from pin hole detectors to inspection equipment in the steel, paper, wood, glass, and textile industries.

A large and growing area for the aperture fluorescent lamp is edge lighting in signs and displays. Since aperture lamps are inherently uniform along the lamp’s length, small diameter lamps have allowed edge lit signs to become more slender, efficient, and significantly brighter with no annoying light bands.

General Specifications

| Reflector | Aperture | |

| OD Range: | 3.0 – 38mm | |

| Length: | 50mm – 2.4 meters | |

| Typical Angles: | 180° to 235° | 2mm – 25mm (dependent on lamp diameter) |

| Shapes: | U, L, Circular, Towel-Bar, and other bent lamp shapes – Consult engineering about your lamp design | |

| Colors: | Virtually any, as required and specified by the customer | |

| Technology: | HCFL and CCFL lamps |

Custom Solutions

Our custom solutions for both lamp types include:

- Diameters as small as 3mm, depending upon the design of the lamp.

- Apertures added to bent lamps.

- Standard phosphors can be blended for customization, matching your exact color requirements in a wide range within the visible spectrum. Standard colors include cool white, warm white, daylight, blue, green, red, ultraviolet, infrared, and tri-band.

- For all OEM lamps, Custom etch and special end caps are available. Ceramic end caps improve appearance and make installation easier.

We can custom manufacture lamps to your specifications- Reflector angles and Aperture lamps to our clients’ exact requirements.

Learn more! Click to download a typical design drawing for an aperture lamp configuration.