Table of Contents

UV Light as a Proven Disinfection Strategy

Ultraviolet (UV) light in the UV-C range (200–280 nm) is a well-established method for inactivating harmful microorganisms. At the germicidal wavelength of 254 nm, UV-C light penetrates microbial cell walls and disrupts DNA or RNA replication, effectively rendering bacteria, viruses, and fungi inactive. This photochemical damage prevents reproduction and transmission, making UV-C one of the most reliable non-chemical disinfection tools available.

Ultraviolet (UV) light in the UV-C range (200–280 nm) is a well-established method for inactivating harmful microorganisms. At the germicidal wavelength of 254 nm, UV-C light penetrates microbial cell walls and disrupts DNA or RNA replication, effectively rendering bacteria, viruses, and fungi inactive. This photochemical damage prevents reproduction and transmission, making UV-C one of the most reliable non-chemical disinfection tools available.

UV-C disinfection is widely used in laboratories, public spaces, and hospitals to reduce healthcare-associated infections (HAIs). It’s also applied in HVAC systems, food processing lines, aquaculture facilities, and municipal water treatment plants to maintain disinfected conditions without harsh chemicals. From high-touch surfaces to recirculated air and water, germicidal UV solutions provide efficient, scalable protection against pathogens.

This article explores how UV light technology combats a range of microbial threats, including Candida auris, E. coli, and SARS-CoV-2, and highlights innovations like Far UVC that expand its safe use in occupied spaces. You’ll also learn how different lamp types and delivery systems enhance disinfection outcomes across environments and industries.

How UV Germicidal Lamps Work

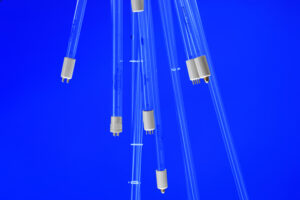

Germicidal UV lamps are engineered to emit shortwave ultraviolet radiation, most commonly at 254 nm, to destroy the nucleic acids in microorganisms. This process, known as photodimerization, prevents pathogens from replicating by breaking bonds within DNA or RNA strands. Whether installed in a fixed air handler or a portable surface unit, these lamps use precision glass, phosphor blends, and electrode configurations to optimize wavelength accuracy and intensity.

The core UVC germicidal lamp types include:

- Low-pressure mercury lamps – emit a consistent 254 nm wavelength and are commonly used for surface and water disinfection.

- Amalgam lamps – offer higher power and longer life, ideal for industrial and high-capacity systems.

- Excimer and Far UVC lamps (222 nm) – designed for safe use in occupied spaces with promising results in virus inactivation.

Each lamp type serves specific disinfection goals, from air purification in HVAC ducts to sterilizing medical instruments and facility surfaces. The effectiveness of UV lamps depends on factors like exposure time, intensity, distance, and the microbial load present. The lighting engineers at LightSources offer in-depth technical expertise in custom UVC lamp design and engineering, including custom phosphor blends and prototype development. Contact us with questions on our UVC germicidal lamp offerings.

Learn more in our article: How Does a UV Germ Light Work, which includes the mechanics of UV lamp design and pathogen inactivation.

UVC Lamp Technology: From Traditional to Far‑UVC Design

Selecting the right UV lamp type is essential for achieving effective disinfection across various environments. Low-pressure mercury lamps remain a reliable choice for delivering a focused 254 nm output, while amalgam lamps offer greater intensity and extended life for high-volume systems. Medium-pressure lamps provide broad-spectrum output ideal for specialized industrial use. Emerging technologies, such as Far UVC at 222 nm, enable safe disinfection in occupied spaces by minimizing skin and eye penetration, while UV-C LEDs offer compact, energy-efficient solutions for targeted germicidal applications.

Learn more in UVC Virus Killers: Germicidal Lamps & Far UVC, including comparisons of lamp types, safety profiles, and application suitability.

Bacteria Elimination with UV Light

Ultraviolet germicidal irradiation (UVGI) has long been used to eliminate bacterial pathogens in clinical, food processing, and water purification settings. UV-C light disrupts bacterial DNA replication by inducing thymine dimers, which inhibit cell division and lead to cell death. This method is chemical-free, residue-free, and effective against a wide range of gram-positive and gram-negative bacteria.

Ultraviolet germicidal irradiation (UVGI) has long been used to eliminate bacterial pathogens in clinical, food processing, and water purification settings. UV-C light disrupts bacterial DNA replication by inducing thymine dimers, which inhibit cell division and lead to cell death. This method is chemical-free, residue-free, and effective against a wide range of gram-positive and gram-negative bacteria.

Several bacterial species have been extensively studied for UV susceptibility:

- E. coli: Easily inactivated with relatively low UV doses, making it a standard test organism for water treatment systems.

- Listeria monocytogenes: A serious threat in food environments; UV systems can significantly reduce contamination on surfaces and in packaging lines.

- Salmonella: Common in both healthcare and food sectors, Salmonella bacteria respond well to UV disinfection in air, water, and on surfaces.

- Mycobacterium tuberculosis (TB): Airborne bacteria like TB can be reduced through upper-room UVGI systems, especially in high-risk environments.

UV systems are widely integrated into air purifiers, cleanroom fixtures, and industrial conveyors to control bacterial contamination. These systems offer rapid, continuous disinfection without the risks associated with chemical antimicrobials.

Learn more about Killing Bacteria with UV Light, including target dose ranges and application examples across multiple industries.

UV Light Against Viruses

Viruses are acellular microorganisms that depend on a host to replicate, making them uniquely susceptible to nucleic acid damage from UV-C exposure. At the 254 nm wavelength, UV-C light penetrates viral capsids and disrupts RNA or DNA, rendering viruses unable to infect host cells. This makes UV disinfection an effective method for inactivating both enveloped and non-enveloped viruses.

Studies confirm the potent efficacy of UV-C light against:

- SARS-CoV-2 (COVID-19): Research shows that SARS-CoV-2 and similar coronaviruses can be inactivated with a UV dose as low as 1.2–1.8 mJ/cm² for 90% viral load reduction. UV-C has become a valuable tool for disinfecting high-touch surfaces, HVAC coils, and patient rooms.

- Influenza A and B: UVGI has been shown to reduce flu transmission in clinical and public spaces when used in combination with standard cleaning protocols.

- Norovirus and Rotavirus: These non-enveloped viruses require higher UV doses but can still be effectively managed with well-calibrated UV disinfection systems.

UV-C is frequently used in air purifiers, isolation room upper-air fixtures, and surface disinfection units in hospitals, transportation hubs, and commercial spaces. Its ability to provide fast, residue-free deactivation supports pandemic preparedness and seasonal outbreak mitigation.

Learn more in Does UV Light Kill COVID?, including viral dose-response data, room applications, and public health integration strategies, and find high-quality UVC lamps for SARS-CoV-2 virus applications.

UV Light for Candida auris and Other Fungi

Fungal pathogens like Candida auris present a growing threat in healthcare environments due to their resistance to antifungal treatments and ability to survive on surfaces for extended periods. UV-C light provides an effective, chemical-free method of inactivating fungi by damaging their cellular DNA and inhibiting reproduction.

Among the most concerning pathogens is Candida auris, a multidrug-resistant yeast that spreads rapidly in hospitals and can lead to severe invasive infections. According to a study published by the American Journal of Infection Control, UV light disinfection systems can inactivate over 99.97% of C. auris on surfaces within seven minutes of continuous exposure at 254 nm. This makes UV-C an essential complement to manual cleaning, particularly in patient isolation rooms and high-risk units.

UV-C has also demonstrated efficacy against other fungal threats such as Aspergillus and Fusarium species, which pose risks in immunocompromised patients. Effective integration of UV systems into HVAC ducts or upper-room fixtures can reduce airborne fungal spores and help maintain clean environments in operating suites, ICUs, and transplant wards.

Learn more in Does UV Light Kill Candida auris?, including UVC dosage benchmarks, disinfection times, and clinical evidence supporting UV’s role in fungal pathogen control.

How UV-C Kills Germs at the Molecular Level

Germicidal UV light works by disrupting the nucleic acids of microorganisms. At wavelengths between 200–280 nm, especially 254 nm, UV-C penetrates the cell walls of bacteria, viruses, and fungi to damage their DNA or RNA. This damage forms pyrimidine dimers that prevent replication and ultimately render the organism inactive or noninfectious.

The degree of inactivation depends on several variables:

- Wavelength and intensity of the UV source

- Distance and exposure time between the lamp and the microorganism

- Type of pathogen (e.g., spore-forming bacteria and viruses may require higher doses)

- Environmental conditions, such as air movement, surface type, or organic load

Understanding these parameters is essential for designing effective UV disinfection systems, whether for surface sterilization, air purification, or water treatment. For a deeper dive into the science of UV disinfection, including the role of photon energy and dimer formation, read How Does a UV Germ Light Work?.

Measuring Germicidal Effectiveness: Factors That Impact UV-C Disinfection

The germicidal performance of UV-C systems depends not only on the type of pathogen but also on several key environmental variables. Microorganisms differ in their susceptibility to UV radiation, with bacterial spores and certain fungi requiring higher doses than enveloped viruses or common bacteria. System efficacy is also influenced by factors such as reflectivity of surrounding surfaces, air flow patterns, humidity, and organic load.

A laboratory study led by researchers at Boston University and supported by Signify Research found that SARS-CoV-2 can be effectively inactivated on surfaces with short-duration exposure to 254 nm UVC light. The researchers exposed both wet and dried samples of the virus to UVC at an irradiance level of 0.849 mW/cm², testing exposure times from under 1 second to 2 minutes. Their results showed that viral infectivity dropped below detectable limits within approximately 4 seconds for wet samples and 9 seconds for dried ones, demonstrating the rapid disinfection potential of UVC light under controlled conditions.

The EPA reviewed UVC efficacy for COVID surface disinfection, reporting a median dose of ~3.6 mJ/cm² for a 90% reduction. Our article How Effective Is UV Light to Kill Germs provides more information on the many benefits of UVC germicidal lamps in various disinfection applications. Learn how to optimize exposure conditions to achieve reliable inactivation rates across a wide range of applications.

Learn more about Understanding UVC Technology: How Germicidal UV Systems Target Pathogens in Air, Water, and Surfaces.

Applications and Considerations for UV Germicidal Systems

Germicidal UV-C light is a scientifically proven method for inactivating harmful pathogens across a wide range of environments. From purifying air and water to disinfecting hard surfaces in critical facilities, UV-C offers chemical-free microbial control that’s fast, effective, and residue-free. LightSources supports OEMs, facilities managers, and healthcare engineers with high-performance UVC lamp technologies engineered for these core application areas.

Air Disinfection

Airborne pathogens are a major concern in healthcare settings, public transportation, and high-occupancy commercial spaces. UV-C disinfection systems placed in HVAC ducts, upper-room air units, or standalone air purifiers expose circulating air to germicidal light, inactivating viruses, bacteria, and fungal spores before they recirculate. Proper placement and lamp selection ensure sufficient dwell time for high inactivation rates.

Airborne pathogens are a major concern in healthcare settings, public transportation, and high-occupancy commercial spaces. UV-C disinfection systems placed in HVAC ducts, upper-room air units, or standalone air purifiers expose circulating air to germicidal light, inactivating viruses, bacteria, and fungal spores before they recirculate. Proper placement and lamp selection ensure sufficient dwell time for high inactivation rates.

Surface Disinfection

Surfaces in hospitals, restaurants, and shared public spaces harbor infectious agents even after routine cleaning. UV-C systems deliver rapid, targeted exposure to high-touch areas including doorknobs, bed rails, tabletops, and prep counters. Surface-mounted fixtures and mobile UV units are commonly used in patient rooms, surgical suites, and food service environments.

Learn more about Surface DisinfectionUV Water Purification

In aquaculture, life sciences, and industrial processing, UV water purification helps ensure microbial safety without introducing chemicals or byproducts. Low-pressure and amalgam UVC lamps in closed-flow systems destroy waterborne bacteria, viruses, and protozoa by damaging their DNA. Quartz sleeves maximize light transmittance and simplify maintenance.

Learn more about UV Water PurificationHospital Disinfection

Healthcare facilities rely on germicidal UV to control infection risks in critical environments. UV-C is commonly used for terminal room disinfection, surgical areas, ICU units, and shared patient equipment. It complements manual cleaning by reducing microbial loads in hard-to-reach areas. UVC also plays a vital role in air handling units to minimize airborne transmission.

Learn more about UV Disinfection in HospitalsRestaurant and Food Service

Food safety requires strict microbial control in prep zones, kitchen ventilation systems, restrooms, and customer touchpoints. UV-C lamps are used to disinfect surfaces, utensils, and airflow, offering an effective alternative to chemical cleaning agents. Restaurants benefit from reduced cross-contamination and cleaner environments with minimal labor or downtime.

Learn more about UV Disinfection in RestaurantsTechnical Factors that Influence UV System Performance

Required Dosage – Each microorganism has a specific inactivation threshold measured in mJ/cm². While enveloped viruses such as SARS-CoV-2 require relatively low doses, bacterial spores and fungi often need significantly higher UVC exposure. System designers must consider lamp intensity, exposure time, and distance to achieve effective disinfection.

Required Dosage – Each microorganism has a specific inactivation threshold measured in mJ/cm². While enveloped viruses such as SARS-CoV-2 require relatively low doses, bacterial spores and fungi often need significantly higher UVC exposure. System designers must consider lamp intensity, exposure time, and distance to achieve effective disinfection.

Material Compatibility – Prolonged UV-C exposure can degrade certain plastics, elastomers, and surface coatings. Materials near UVC sources should be evaluated for long-term tolerance, and shielded where necessary to preserve integrity and performance.

Emerging Technologies – Far UVC (222 nm) – Far UVC presents a major advancement in safety for occupied-space disinfection. With lower skin and eye penetration, 222 nm light can inactivate airborne and surface pathogens without harming human tissue. While still undergoing long-term validation, Far UVC is being integrated into ceiling fixtures, waiting rooms, and public transit infrastructure.

LightSources offers a comprehensive portfolio of UV-C lamps for air, surface, and water disinfection, with engineering support to help customers select or design the optimal solution for their facility. Our proprietary technologies, such as LongLife+™ for extended lamp performance and Shatter ProTech™ for glass containment, enhance both safety and service life.

UV-C in a Comprehensive Infection Control Program

Integrating UV-C technology into broader infection control protocols enhances the overall efficacy of pathogen reduction strategies. When combined with manual surface cleaning, EPA-approved chemical disinfectants, and air purification technologies such as HEPA filtration, UV-C provides an additional layer of microbial inactivation that reduces reliance on chemicals and minimizes gaps in coverage. This layered approach has proven valuable in healthcare facilities, commercial kitchens, and public transportation systems, where cross-contamination risks are high and downtime must be limited. UV-C systems offer the advantage of repeatable disinfection cycles with measurable dose control, improving long-term hygiene consistency while supporting sustainability goals.

Learn how UV-C disinfection strengthens multi-tiered sanitation programs, Harnessing the Power of UVC Disinfection to Combat Germs.

Final Thoughts: UV Light as a Reliable Defense Against Germs

UV-C disinfection stands as one of the most effective non-chemical strategies for neutralizing a wide range of pathogens, including bacteria, viruses, fungi, and drug-resistant organisms. Its success lies in the direct damage UV-C causes to DNA and RNA, preventing reproduction and rendering pathogens inactive. From airborne microbes to waterborne threats and contaminated surfaces, germicidal UV systems provide scalable protection for hospitals, food service, transportation, and industrial environments.

As antimicrobial resistance rises and hygiene standards become more stringent, demand for UV-C technology continues to grow. LightSources remains at the forefront with high-output UVC germicidal lamps, advanced quartz sleeve technologies, and proprietary features that improve longevity, safety, and system performance. Our engineering team works directly with OEMs to develop application-specific UV solutions that meet rigorous performance and compliance standards.

LightSources Delivers Proven UV-C Germicidal Solutions

LightSources is a global leader in the design and manufacture of germicidal UV bulbs for disinfection systems targeting air, water, and surfaces. We offer advanced UVC lamp technologies, including low-pressure, amalgam, and specialty wavelengths like 222 nm Far UVC to meet the evolving needs of OEMs, engineers, and facility managers.

LAMP PRODUCT DATA:

UV Germicidal LampsLAMP APPLICATIONS:

UV Germicidal ApplicationsLightSources provides advanced UVC germicidal lamp solutions for air, surface, and water disinfection. Our engineering team supports OEMs with custom UV technologies designed to meet strict performance, safety, and microbial reduction requirements. Contact us to explore custom-engineered UV solutions designed to combat today’s toughest pathogens.