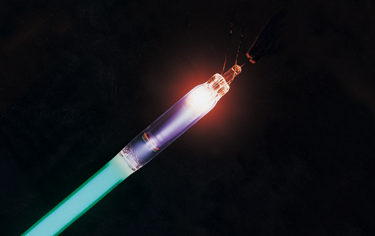

Neon Electrodes for Sign Lighting

Through our precise manufacturing techniques, overseen by engineers with a tremendous commitment to quality, Voltarc produces Masonlite MilleniumTM Neon Electrodes – the unrivaled choice for signage professionals worldwide.

At Voltarc we use the best raw materials, including shells deep drawn from the finest-quality, pure soft iron, and nickel plated in a custom-built, dedicated plant. The result is first-rate electrodes without the risk of contamination.

At Voltarc we use the best raw materials, including shells deep drawn from the finest-quality, pure soft iron, and nickel plated in a custom-built, dedicated plant. The result is first-rate electrodes without the risk of contamination.

Our lead wires are made of standard nickel wire for corrosion-resistance and flexibility, along extra length of copper-clad Dumet sealed into the pinch to enhance confidence in the metal-to-glass seal, and solid-nickel wire for high purity and low outgassing, attached to the shell for reliability via a welding method pioneered by Masonlite.

Masonlite Millennium™ Neon Electrodes – Bombarding and Pumping Procedure

The following procedure is for 15/50C and 15/50CT electrodes on 15mm or larger diameter coated Sign Tubing. Adjust the procedure for other electrode sizes, smaller diameter tubing, and tubes less than 18″ long.

Preheat

- Open vacuum valve and evacuate tube to approximately 2 to 3 Torr (2 to 3 mm Hg) pressure. Close vacuum valve.

- Turn on bombarder and bring current to between 150 and 200 mA.

- Continue bombarding until the tube reaches 275° to 300°F (135° to 150°C). Always release bombarder switch prior to opening of main stopcock. Then open vacuum valve. Evacuate tube(s) for 45 to 60 seconds, depending on tube length and configuration.

Step 2

Close vacuum valve, refill tube(s) with 2 to 3 Torr

Close vacuum valve, refill tube(s) with 2 to 3 Torr

(2 to 3 microns) of dry air.- Turn on bombarder and raise current to 325 mA;

continue heating until tube reaches 375° to 400°F

(190° to 205°C). Note: for uncoated tubes, heat to

482°F (250°C). At this point reduce pressure to 1 Torr

or slightly less.

Step 3

- Increase current to 800 mA.

- Bring neon electrode shells to a bright, cherry-red color, (1,652° to 1,832°F (900° to 1,000°C)) while maintaining ½ to 1 Torr pressure. Once all shells are of a uniform color, release the bombarder switch and open the vacuum valve.

- Evacuate the tube(s) to the lowest possible pressure – at least 3 to 5 millitorr (3-5 microns). Continue pumping until you can comfortably handle the tube(s) – about 122 °F (50°C).

- Release accumulated moisture in the tabulation(s) at this time with the aid of a heat gun or hand torch. This prevents transfer of moisture to the finished tube(s) during flushing and/or backfilling of the inert gas(es).

- Backfill the tube(s) to the designated pressure with the desired gas using a positive pressure gauge if possible.

| Masonlite Millennium™ Electrode Type |

Preheat Current Pressure |

Step 2 Pressure |

Step 3 Pressure |

| 12/30C | 150 mA | 225 mA | 450 mA |

| 12/30CT | |||

| 13/30C | 2 Torr | 2 Torr | 1 Torr |

| 13/30CT | |||

| 12/25C | 75 mA | 125 mA | 300 mA |

| 12/25CT | |||

| 13/25C | 2 Torr | 2 Torr | 1 Torr |

| 13/25CT | |||

| 15/30C | 150 mA | 225 mA | 450 mA |

| 15/30CT | 2 Torr | 2 Torr | 1 Torr |

| 15/50C | 200 mA | 325 mA | 800 mA |

| 15/50CT | 2 Torr | 2 Torr | 1 To |

Masonlite MillenniumTM Electrodes

Lead Glass Electrodes: Mica Disc – Ceramic Collar – Premium Steel Shell

| Part #1 | Description2 | Rating (mA) | Glass Length |

| 20270 | 10/20C-2 | 20 | 2″ |

| 20271 | 10/20CT-2 | 20 | 2″ |

| 20304 | 12/25C-2 | 25 | 2″ |

| 20305 | 12/25CT-2 | 25 | 2″ |

| 20274 | 12/30C-2 1/2 | 30 | 2 1/2″ |

| 20275 | 12/30CT-2 1/2 | 30 | 2 1/2″ |

| 20276 | 13/25C-2 | 30 | 2″ |

| 20277 | 13/25CT-2 | 30 | 2″ |

| 20282 | 13/30C-2 1/2 | 30 | 2 1/2″ |

| 20283 | 13/30CT-2 1/2 | 30 | 2 1/2″ |

| 20285 | 15/30C-2 3/8 | 45 | 2 3/8″ |

| 20286 | 15/30CT-2 3/8 | 45 | 2 3/8″ |

| 20288 | 15/50C-2 3/4 | 80 | 2 3/4″ |

| 20289 | 15/50CT-2 3/4 | 80 | 2 3/4″ |

| 20298 | 18/120C-3 | 120 | 3″ |

| 20299 | 18/120CT-3 | 120 | 3″ |