Main Characteristics of Alumina Ceramic:

- High melting point

- Mechanical strength

- Hardness

- Wear resistance

- Heat resistance

- Heat conduction capacity

- Electrical insulation capacity

- Acid and alkali resistance

Our products are made of various material grades depending on the application requirements. The materials differ highly from each other depending on their Al2O3 content, wear and heat resistance, insulation capacity and color.

So, depending on your unique requirements, we can help you determine which material would work best in your application environment.

| The Ceramic Process |

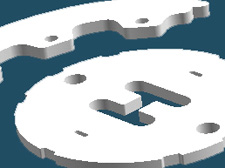

Press Injection Molding

A significant part of our products is made with low pressure press injection-molding which has the advantage of gaining products with complicated shape and thin wall. Due to our state-of-the-art manufacturing capabilities, manufacturing costs is kept low which enables us to offer high quality products at competitive prices.

|

|

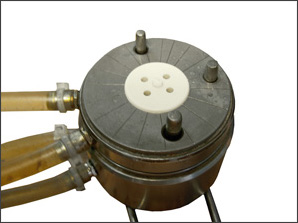

Stamping

Extremely compact ceramic parts can be made with a hydraulic pressing machine. The power we use contains 92-94% alumina (Al2O3). Some of the customized ceramic parts we produce with this technology includes: electric insulators, wear resistant grinding cylinders, tips, washers and more.

Firing

The firing of ceramic products is carried out at high temperature in both, electric or natural gas operated furnaces of 1-2 m3, at 1.0000C or 1.60000C.

At Cerlux we are constantly evaluating our impact on the environment and have long term aims to recycle, reuse, and reduce our waste. For example, to produce hot water and heat our entire office and manufacturing buildings, we recycle the heat from our kiln…

Glazing

Fired glazing increases material strength and also provides bright, aesthetic surfaces. In general, glazing is highly recommended to protect the surfaces of ceramic products. White glaze coating – either mat or bright – is the preferred color in many industries. However, depending on our customer’s requirements, we can offer any color in the RAL or pantone palette.

Fired glazing increases material strength and also provides bright, aesthetic surfaces. In general, glazing is highly recommended to protect the surfaces of ceramic products. White glaze coating – either mat or bright – is the preferred color in many industries. However, depending on our customer’s requirements, we can offer any color in the RAL or pantone palette.

A colored component can add substantial value and uniqueness to your system:

- Ceramic parts that match your corporate colors

- Identify your product lines with uniquely colored system parts to provide your customers ease-of-use, while reducing system implementation errors

- Set your system apart from your competitors

- Enjoy greater flexibility in your system designs

Decal

After the glazing process, a decal can be applied to the product. It can be your company’s logo, a phone number, part number or a simple tagline – a decal on your ceramic parts can certainly make your system components stand out. Simply put, decals are a great marketing tool used to differentiate you from your competitors.

After the glazing process, a decal can be applied to the product. It can be your company’s logo, a phone number, part number or a simple tagline – a decal on your ceramic parts can certainly make your system components stand out. Simply put, decals are a great marketing tool used to differentiate you from your competitors.

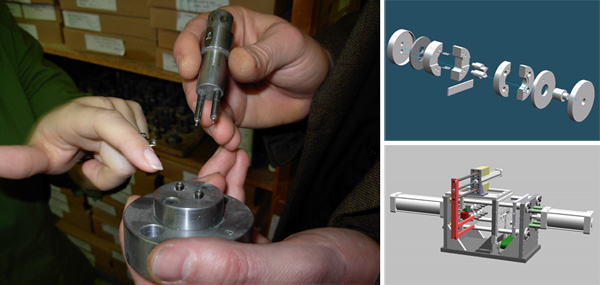

Tool Engineering

Ceramic manufacturing is a highly specialized procedure requiring customized machinery that allows us to cost effectively handle high volume orders while ensuring a constant precise quality. At Cerlux the engineers and developers are continuously working on improving production processes, by designing our own tools in-house. Tools are engineered with the most up-to-date 3D compatible software. Various precision machines like sparking, grinding and milling machine.

Ceramic manufacturing is a highly specialized procedure requiring customized machinery that allows us to cost effectively handle high volume orders while ensuring a constant precise quality. At Cerlux the engineers and developers are continuously working on improving production processes, by designing our own tools in-house. Tools are engineered with the most up-to-date 3D compatible software. Various precision machines like sparking, grinding and milling machine.

Click here for more information or any further questions about Cerlux.