For consistent color performance and excellent durability, Voltarc sign tubing offers the proprietary Rotronic Color Guard coating process to assure uniformity of coating thickness along the whole length of the tube. Together with our exacting quality control measures, this process ensures high performance and exceptional reliability.

We are also able to achieve consistency in weight – from top to bottom, batch to batch and year to year. And all this leads to consistency in lumen output, so our ultimate performance matches the consistency of our process.

LongLife

Long lamp life means better performance, lower operational costs and fewer maintenance issues and expenses for the sign industry. Voltarc components perform over exceptionally long lifetimes, thanks to the extensive research and development work of engineers who are unfailingly committed to quality.

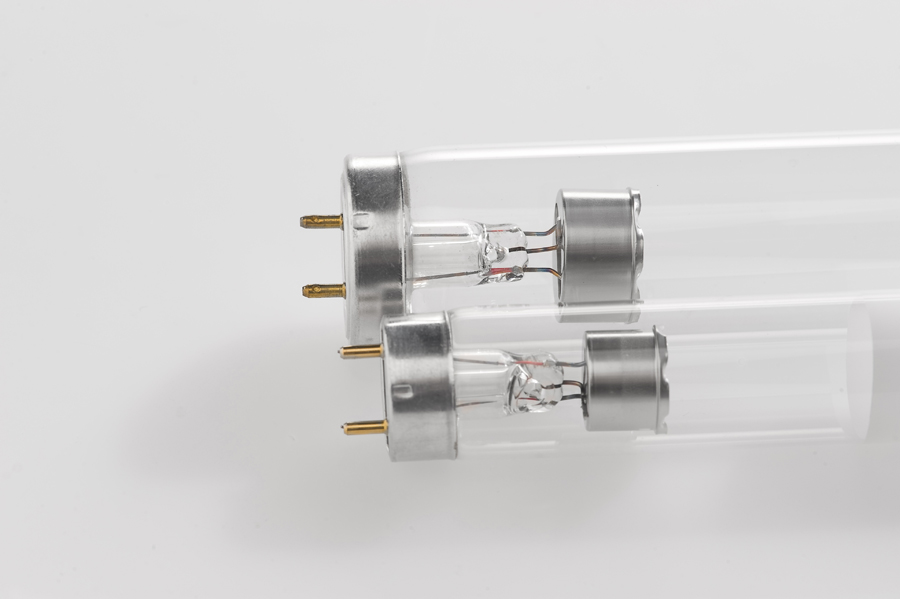

A key to this system is our uniquely designed Cup-Cathode Technology – a protective shield that fully encloses the filament. Not only does this innovation provide extremely long electrical life, it also prevents filament emission coating sputter from entering the arc stream, which guards against lumen depreciation.

Combined with Voltarc’s custom blended high-maintenance, high-color rendering index (CRI) tri-band Cool White, Daylight or 5000° K phosphor, we can provide lamp performance up to 60,000 hours!

Ground Fault Protection

Ground Fault Protection

Kulka lampholders are the leading choice for the sign professional. Kulka’s patented Dead Front housing design protects against ground faults by eliminating rivets in the lampholder face, thus completely isolating it from the ground.

A key to this technology is our FabulexTM mounting clip, which is built from specially-formulated, engineering-grade thermoplastic to deliver Tensile Elongation strength of -68° F to 158° F, and Shear Strength of 9,000 PSI.

Voltarc adds to this system our patented O-Ring design – a molded undercut in the housing that is especially beneficial for re-lamping. The O-Ring has the effect of negating pull-out, while its round face shape resists bonding to lamp ends. Its blue silicone treatment resists water and condensation, which prevents bonding during re-lamping. It delivers consistent long life and requires no drying.

The wire and contact assembly also benefits from effective moisture protection and strain relief, with a specially-formulated pitch range temperature of -85° F to 225° F.

Spring-tempered, silver-plated phosphor bronze contacts are precisely set to ANSI standards to provide optimal lamp-to-lampholder contact alignment, thus resisting arcing and delivering longer life. At the same time, spring tension consistently meets or exceeds ANSI specifications, maintaining positive contact pressure. The system achieves proper lamp alignment in all applications with a self-aligning lampholder face for a true fit all the time.

Our White Urea Housing is molded to exacting specifications, which ensures consistent fit in knock-out, and is designed for a super-wide temperature range to eliminate cracking, shrinking and contracting.

UL-listed and CSA-approved, the system meets or exceeds UL48 and CSA C22.2 No. 43-M1984 for all applicable ballasts in outdoor enclosed signs. It also enjoys the highest power rating:

- 660W, 1000 Volt UL and CSA Listed

- AWM style 1015 VW1 105 degrees Celsius/600 volts, 1032 90 degrees Celcius/1000 volts

- Dual rated wire leads ensure proper electrical interface to the ballast wiring system.