The process of UV ink curing has been around since the 1960’s and uses high intensity ultraviolet light to create a photochemical reaction. By using the proper intensity of UV wavelengths, a byproduct is produced that hardens resin and dries  inks. It offers numerous advantages over traditional heat-cured systems and has become the method of choice for many as it safely and cost-efficiently cures inks, as well as adhesives, coatings, varnishes, decorative glazes and lacquers.

inks. It offers numerous advantages over traditional heat-cured systems and has become the method of choice for many as it safely and cost-efficiently cures inks, as well as adhesives, coatings, varnishes, decorative glazes and lacquers.

UV Curing Benefits

UV ink curing systems are easy to operate and maintain and more environmentally-friendly than traditional systems. Since UV ink curing does not produce noxious fumes as heat-cured inks, it does not require expensive exhaust systems to counteract the fumes. UV systems are used by industries such as automotive, electrical, industrial, and medical.

Another benefit of curing inks with UV light is that the ink dries instantaneously, which greatly speeds up production times as well as helps to improve the overall quality of the product. The speedy drying time means products are ready for shipment much quicker and the chance of dust or other airborne objects ruining the finished product is reduced.

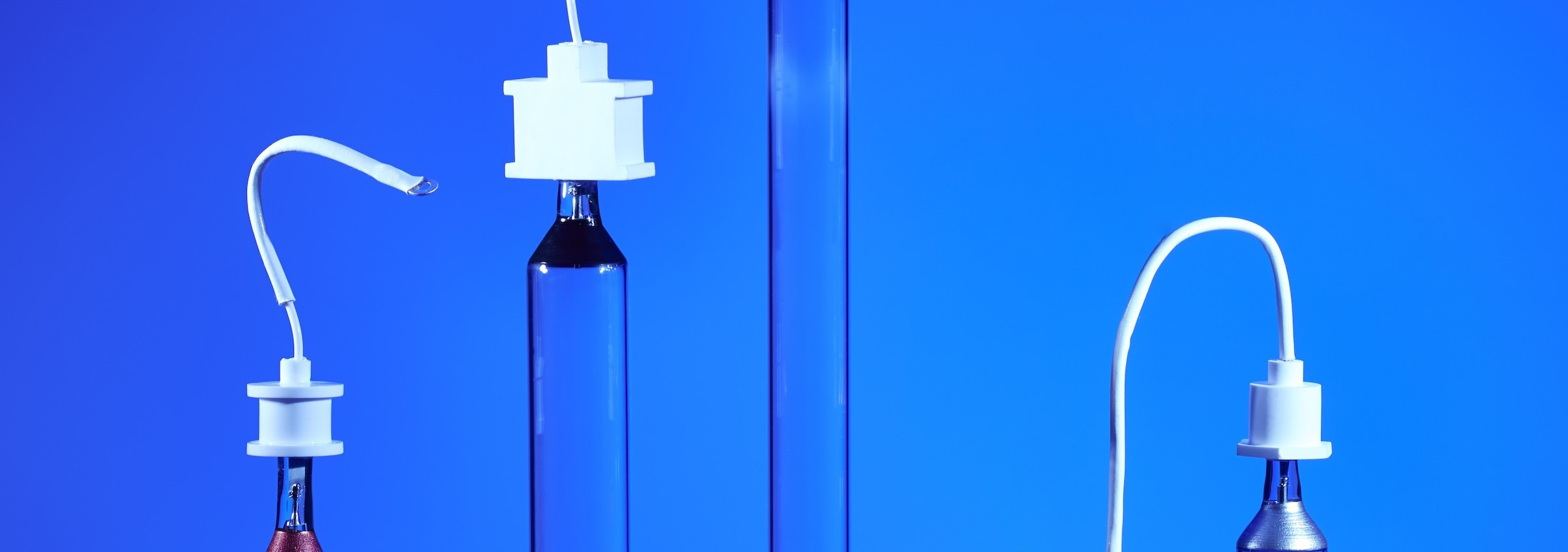

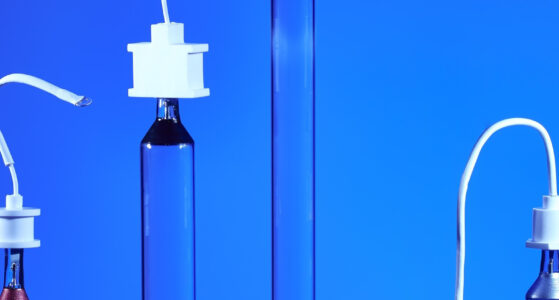

UV Ink Curing Lamps

The types of UV lamps used for UV ink curing includes low pressure and medium pressure UV (MPUV) curing lamps as well as amalgam UV curing lamps. Using a wavelength of 254nm, UV low pressure lamps are used to cure inks in high-quality magazines and newspapers. In addition since low pressure lamps operate on much less power than MPUV lamps, they are ideal for applications requiring dimming.

MPUV lamps are the best choice for applications that require a higher intensity of UV light due to shorter exposure times and need high-speed press runs. Also there are some industries that prefer amalgam lamps for the efficient drying of inks and adhesives with a cationic base. Amalgam lamps produce outputs of 300 to 1000 watts, of which one-third is usable UVC energy, and offer the opportunity to downsize a system while still maintaining maximum efficiency for UV curing.

With the combined resources of LightSources in the U.S. and LightTech in Europe, we are global leaders in UV curing lamps as well as UV air treatment systems. We partner with OEMs of any size to design, engineer and mass-produce new types of proprietary and specialty lamps cost-effectively and with short turnaround. Contact us for more details regarding our technological advanced lamps for UV ink curing.