Table of Contents

- 1 LightSources High-Quality Replacements for Superior Quartz UV Curing Lamps

- 2 The Critical Role of Superior Quartz UV Lamps in Industrial Curing

- 3 The Need for Reliable Superior Quartz UV Curing Lamp Replacements

- 4 Understanding High-Power UV Lamps for Curing

- 5 Benefits of UV Curing Lamps in Applications

- 6 Applications of High Power Superior UV Curing Lamps

- 7 LightSources’ Solutions for High-Power UV Curing Lamps

- 8 Benefits of Choosing LightSources for Superior Replacement UV Lamps

LightSources High-Quality Replacements for Superior Quartz UV Curing Lamps

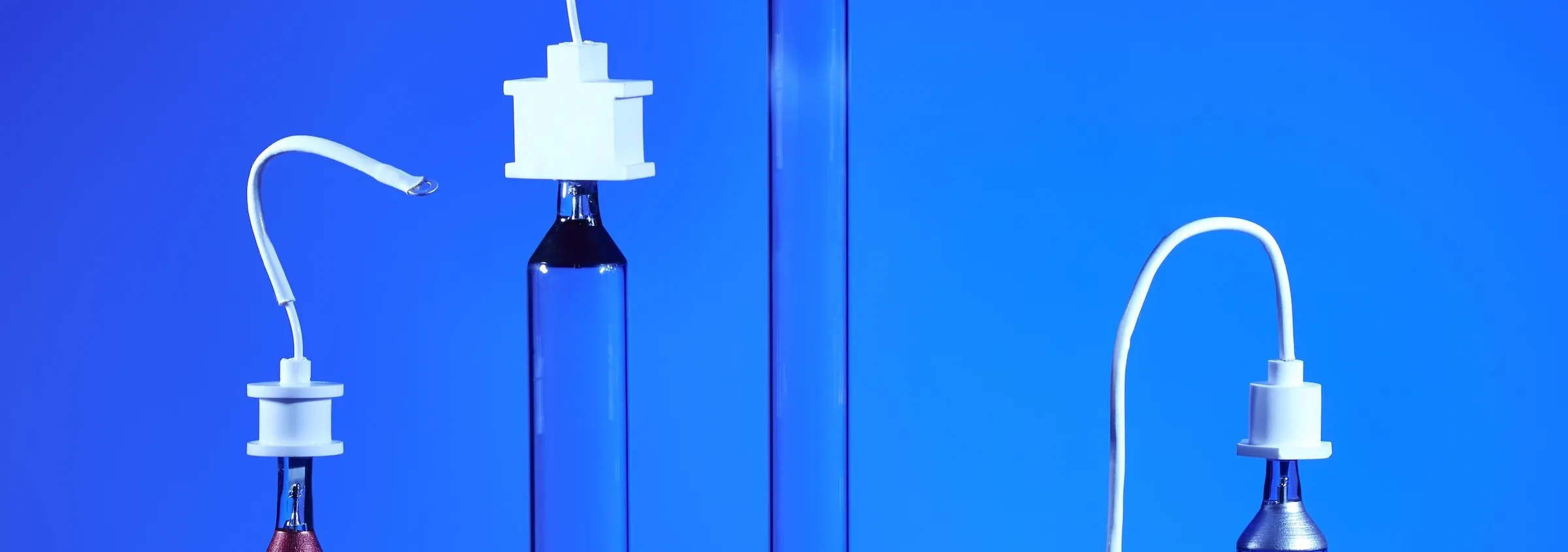

Superior Quartz UV curing lamps, specifically medium-pressure UV lamps and high-power metal halide lamps, are a critical component in many industrial applications. Superior Quartz lamps provide varying arc lengths and watts per inch to achieve high-quality and efficient curing solutions for many industries. Various manufacturing applications rely on UV curing lamps to enhance production.

The Critical Role of Superior Quartz UV Lamps in Industrial Curing

High-power ultraviolet (UV) lamps are indispensable in industrial curing applications, providing the intense UV radiation necessary to initiate rapid drying and hardening of materials. Superior Quartz lamps play a crucial role in processes involving adhesives, coatings, inks, and varnishes, where they facilitate photochemical reactions that transform liquids into durable solids within seconds. Industries such as printing, automotive, electronics, and manufacturing rely on high-power UV lamps to enhance production speed, improve product quality, and reduce energy consumption.

The importance of these lamps lies in their ability to:

- Increase Efficiency: By significantly reducing curing times, high-power UV curing lamps boost production rates and minimize bottlenecks in manufacturing lines.

- Improve Product Performance: UV curing ensures stronger bonds and more uniform finishes, leading to higher-quality end products.

- Offer Environmental Benefits: UV curing processes emit fewer volatile organic compounds (VOCs) compared to traditional methods, contributing to a safer workplace and reduced environmental impact.

LightSources offers UV curing solutions with high-performance Superior Quartz UV curing lamp replacement products and custom solutions, including prototype development and proprietary OEM solutions.

The Need for Reliable Superior Quartz UV Curing Lamp Replacements

As industries evolve and the demand for advanced UV curing solutions grows, OEMs and businesses must have high-quality replacements for Superior Quartz UV lamps to maintain optimal operation of their equipment. The need for reliable, high-performance UV lamps is more pressing than ever to ensure uninterrupted production and adherence to quality standards. Access to compatible, high-quality Superior Quartz alternatives is crucial for companies aiming to enhance efficiency and stay competitive in their respective markets.

LightSources recognizes this need and offers high-quality, high-performance UV curing lamps that serve as excellent replacements for Superior Quartz UV curing lamps. With extensive expertise in custom lamp design, engineering, and prototype development, LightSources provides OEMs and businesses with innovative UV lamp solutions custom-designed to their specific requirements.

Understanding High-Power UV Lamps for Curing

High-power ultraviolet (UV) lamps are specialized light sources that emit intense UV radiation used to initiate chemical reactions in various industrial processes. The two primary types of high-power UV lamps utilized in curing applications are medium-pressure UV lamps and metal halide UV lamps.

High-power ultraviolet (UV) lamps are specialized light sources that emit intense UV radiation used to initiate chemical reactions in various industrial processes. The two primary types of high-power UV lamps utilized in curing applications are medium-pressure UV lamps and metal halide UV lamps.

- Medium Pressure UV Lamps: These lamps operate at internal pressures ranging from 1 to 10 atmospheres and produce a broad spectrum of UV light, including UVA, UVB, and UVC wavelengths. Their high intensity makes them ideal for applications requiring rapid curing and deep penetration of UV energy into materials.

- Metal Halide UV Lamps: Similar to medium-pressure lamps but doped with metal halide additives, these lamps emit UV light at specific wavelengths tailored to the curing requirements of particular materials. The additives allow for customization of the spectral output, enhancing the curing of specialized inks, coatings, and adhesives.

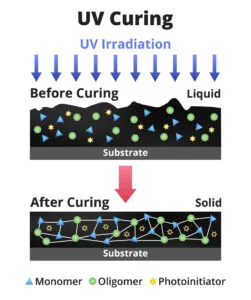

Both types function by emitting intense UV radiation that triggers photochemical reactions in materials formulated to respond to UV light. When exposed, the photoinitiators within these materials absorb the UV energy, causing them to polymerize and harden almost instantaneously. This process transforms liquids or gels into solid forms, completing the curing cycle efficiently.

Benefits of UV Curing Lamps in Applications

High-power UV lamps provide numerous advantages in industrial curing, significantly enhancing both the efficiency and quality of production processes. By utilizing these lamps, manufacturers can achieve faster curing times and superior product performance, which is essential in today’s competitive markets. LightSources UV curing lamps provide the same benefits as Superior Quartz curing lamps, improving efficiency and product effectiveness across a wide range of applications.

Efficiency and Effectiveness

Efficiency and Effectiveness

- Rapid Curing Times: High-power UV lamps significantly reduce the time required to cure materials compared to traditional thermal drying methods. The immediate initiation of polymerization upon UV exposure allows for faster production cycles, increasing throughput and operational efficiency.

- Improved Product Quality: The use of UV curing ensures a consistent and thorough cure, resulting in stronger bonds and more durable finishes. This uniformity enhances the performance and longevity of the final products, meeting high-quality standards demanded by industries.

Versatility

- Wide Range of Industrial Applications: High-power UV lamps are suitable for numerous industries due to their ability to cure a variety of materials. They are integral in processes involving adhesives, coatings, inks, and varnishes across sectors like printing, automotive, electronics, and woodworking.

- Adaptability to Complex Materials and Shapes: The intense and targeted UV radiation can penetrate complex shapes and thick layers, allowing for the curing of intricate designs and challenging surfaces. This adaptability makes them valuable tools for manufacturers dealing with diverse product geometries and compositions.

Applications of High Power Superior UV Curing Lamps

Superior UV curing lamps are integral to a wide array of industries due to their ability to efficiently cure materials and enhance production processes. The versatility and effectiveness of LightSources’ UV curing lamps make them valuable in numerous curing applications.

Industrial Uses

- Adhesives: In manufacturing and assembly processes, UV-curable adhesives provide strong bonds in minimal time. High-power UV lamps enable the rapid setting of adhesives used in products ranging from electronics to automotive components.

- Coatings: UV curing is employed for applying protective and decorative coatings on various substrates. The quick curing process enhances surface properties like scratch resistance and gloss without prolonged drying times.

- Inks: The printing industry relies on UV-curable inks for high-speed printing with immediate drying. This technology allows for vibrant colors and high-resolution images on materials such as paper, plastic, and metal.

- Varnishes: UV-curable varnishes offer a durable finish for products like furniture and flooring. High-power UV lamps ensure that these finishes are applied efficiently, providing protection and aesthetic appeal.

Specialized Fields

- Graphic Arts: In applications like screen printing and digital printing, high-power UV lamps cure specialized inks and coatings that enhance visual effects and durability.

- Fiber Optics: The production of fiber optic cables utilizes UV curing to harden protective coatings around delicate glass fibers, ensuring signal integrity and mechanical strength.

- Medical Equipment: UV curing is used to assemble and seal medical devices, where strong bonds and minimal chemical residues are critical for safety and performance.

- Photochemistry: In research and industrial processes involving photochemical reactions, high power UV lamps provide the necessary energy to drive reactions for synthesizing chemicals and materials.

High power UV curing lamps are integral to modern manufacturing and industrial processes, offering efficiency, quality, and versatility. Their ability to meet the demands of various applications makes them essential tools for companies aiming to improve productivity and product performance.

LightSources’ Solutions for High-Power UV Curing Lamps

LightSources’ Solutions for High-Power UV Curing Lamps

LightSources: Leading Global UV Light Supplier

LightSources is a global leader in ultraviolet (UV) lamp technology, renowned for innovation and excellence in the design, engineering, and manufacturing of high-quality UV lamps. With decades of experience, we have established ourselves as a trusted partner for Original Equipment Manufacturers (OEMs) and businesses worldwide. Our expertise spans a wide range of applications, including UV curing, germicidal processes, and specialty lighting solutions.

Our commitment to advancing UV technology has led us to develop cutting-edge products that meet the evolving needs of various industries. By investing in research and development, we continuously improve our lamp technologies to deliver superior performance, energy efficiency, and longevity. Our team of skilled engineers and technicians works closely with clients to understand their specific requirements, enabling us to provide tailored solutions that enhance productivity and product quality.

Manufacturing Capabilities

At LightSources, we possess robust manufacturing capabilities that allow us to produce medium-pressure UV lamps and metal halide UV lamps in a diverse range of sizes and power levels. Our lamps feature:

- Arc Lengths Ranging from 1 Inch to 200 Inches: We can accommodate virtually any equipment size or application requirement, ensuring compatibility and optimal performance.

- Power Ranges from 50 to 2000 Watts Per Inch: Our high-power UV lamps are designed to meet various curing demands, providing the necessary intensity for rapid and effective curing processes.

Utilizing state-of-the-art manufacturing facilities and strict quality control protocols, we ensure that every lamp meets the highest standards of excellence. Whether you need a standard lamp or a custom design, our manufacturing prowess enables us to deliver products that align perfectly with your operational needs.

Reliable High-Quality Replacements

Understanding the critical need for reliable replacement lamps, LightSources offers high-quality, high-performance UV curing lamps compatible with systems previously using Superior Quartz lamps. We recognize that seamless integration is essential to maintain efficiency and consistency in your operations.

Custom Lamp Design, Engineering, & Development

Custom Lamp Design, Engineering, & Development

- Custom Lamp Design and Engineering: We work collaboratively with OEMs to design lamps that match or exceed the specifications of Superior Quartz lamps. Our engineers consider all aspects of your equipment and application to create the ideal solution.

- Prototype Development: Before full-scale production, we offer prototype development to ensure compatibility and performance, allowing for adjustments and optimizations as needed.

By choosing LightSources as your UV lamp supplier, you benefit from our dedication to quality, innovation, and customer satisfaction. We are committed to delivering lamps that not only fit your existing systems but also enhance their performance and longevity.

Benefits of Choosing LightSources for Superior Replacement UV Lamps

When it comes to replacing your Superior Quartz UV curing lamps, partnering with LightSources offers numerous advantages that can elevate your operational efficiency and product quality.

Technological Superiority and Customization

Technological Superiority and Customization

- Advanced Lamp Technologies: Leveraging the latest advancements in UV lamp technology, our products offer superior performance, including higher UV output, improved energy efficiency, and extended operational life. This ensures that your curing processes are optimized for maximum productivity and quality.

- Custom Solutions: We understand that every application has unique requirements. Our ability to provide custom-designed lamps means you receive products tailored to your exact specifications. From specific wavelengths to unique physical dimensions, we deliver solutions that align perfectly with your needs.

- Proprietary Technology: LightSources invests in continual improvement through research and development, offering patented technologies like LongLife+™ technology, a specialty coating that significantly enhances lamp life and end-of-life performance. Shatter ProTech is another LightSources proprietary technology that protects users against injury from shattered glass and mercury exposure with heat and acid resistance. We offer customized, advanced high caliber lampholders and electrical wiring devices with our partner companies Voltarc, Cerlux, and LCD Lighting.

Trust and Reliability

- Committed OEM Support: LightSources is dedicated to supporting OEMs without engaging in direct sales to end-users. This approach fosters trusted partnerships, allowing us to focus on providing our OEM clients the best possible products and services.

- Quality Assurance: Through rigorous testing and quality control processes, we ensure consistent product quality. Our lamps are manufactured to meet stringent industry standards, providing you with reliable and durable solutions that you can depend on.

Continuity and Support

- Seamless Integration: Our replacement lamps are designed to be compatible with existing systems, ensuring a smooth transition without extensive modifications. This continuity minimizes downtime and maintains the efficiency of your operations.

- Ongoing Technical Support: We offer comprehensive technical support and customer service to assist you with installation, troubleshooting, and optimization. Our team of experts is readily available to ensure that your UV curing systems operate at peak performance.

By partnering with LightSources, you can access expertise and resources dedicated to enhancing your UV curing applications. Our focus on technological innovation, quality, and customer support makes us the ideal choice for replacing Superior Quartz high-power UV lamps and advancing your operational capabilities.

LightSources specializes in high-quality high-power UV curing lamps, offering reliable replacements for other UV curing lamp suppliers. With our advanced technology and dedication to innovation, we provide custom solutions that enhance performance and efficiency in your curing applications. Contact us today to discover how our UV lamps can serve as superior replacements for Superior Quartz UV curing lamps.

This post is also available in:

Chino simplificado

Chino simplificado Inglés

Alemán

Alemán