Table of Contents

- 1 UV Curing Solutions at LightSources

- 2 What Is UV Curing?

- 3 Benefits of UV Curing: Faster Processes, Sustainable Results

- 4 UV Curing Applications: Versatility Across Industries

- 5 Precision UV Curing with LightSources Lamp Technologies

- 6 Replacement UV Curing Lamps for Superior Quartz & Primarc Baldwin Systems

- 7 UV Curing Education: FAQs, Glossary, and Downloads

- 7.1 Frequently Asked Questions

- 7.2 How do I choose a wavelength (e.g., 365 nm vs. 395/405 nm) for my chemistry?

- 7.3 What actually determines “dose,” and how do I size my lamp to hit it?

- 7.4 When should I use medium-pressure UV (MPUV) instead of low-pressure UV or LED?

- 7.5 What maintenance has the most significant impact on delivered dose?

- 7.6 How do we ensure the safety of operators working around high-intensity UV?

- 7.7 Glossary of Terms

- 7.8 Technical Downloads

- 8 Elevate Production with UV Curing Lamp Specialists

UV Curing Solutions at LightSources

UV curing is a fast, energy-efficient photochemical process for inks, coatings, and adhesives, delivering near-instant polymerization and consistent results without the need for ovens. LightSources supports OEMs with a whole ecosystem of curing lamps, including medium-pressure, high-pressure, low-pressure/amalgam, and LED-compatible options engineered for precise dose, spectrum, and throughput.

What Is UV Curing?

How UV Curing Works

How UV Curing Works

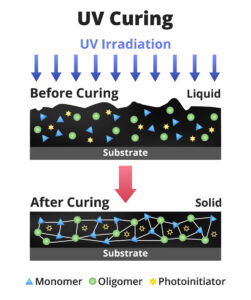

UV curing (also known as UV light curing) utilizes high-intensity UV curing lamps to activate photo initiators in a formulated material, triggering rapid polymerization/cross-linking that converts liquids into durable solids in seconds. Systems are configured around the chemistry and film build:

- Arc/MPUV sources deliver broad-spectrum output for high line speeds and thicker or pigmented layers.

- A 365 nm UV lamp can be ideal for resins and UV curing adhesives whose photo initiators peak in that wavelength range; a high-intensity UV curing lamp is preferred when a deeper cure or higher throughput is required.

Why It’s Effective

Utilizing UV curing light is a photochemical process that requires no solvent evaporation or lengthy cool-down, delivering speed and precision that thermal methods can’t match. You get tight dose control, instant on/off, and room-temperature processing that protects heat-sensitive substrates. Engineers can target specific areas and complex geometries that are hard to heat evenly, achieving a highly consistent cure, hardness, adhesion, and chemical/abrasion resistance, without warping or over-baking.

UV curing light systems offer a compact footprint versus long ovens, which streamlines production lines, reduces WIP, and boosts throughput while improving both product quality and the overall environmental footprint of the process. Curing with UV light offers numerous advantages that improve production processes across a broad range of applications.

Benefits of UV Curing: Faster Processes, Sustainable Results

UV curing systems replace slow, heat-based drying processes with a quick and precise photochemical reaction, resulting in faster lines, cleaner operations, and tighter process control. Some of the most important benefits of curing with UV lamps include:

- Lower emissions & easier compliance: UV-curable inks/coatings are recognized by the EPA as having low or no Volatile Organic Compounds (VOCs) or Hazardous Air Pollutants (HAPs), reducing options that can simplify air permitting and reduce abatement needs.

- Reduced energy use & GHG footprint: UV processes concentrate energy in the coating with light rather than heat, resulting in lower energy demand, fossil fuel use, and greenhouse gas emissions compared to thermal ovens.

- Speed & throughput: UV curing light inks and coatings cure instantly in seconds, supporting higher line speeds, lower WIP (work-in-progress), and shorter takt times —the rate at which you must produce to meet customer demand, often called the heartbeat of a lean system. UV Ink Curing Systems Provide Quick, Effective Results

- Room-temperature processing: Heat-sensitive substrates such as plastics and electronics can be cured without warping, making UV curing ideal for assemblies and intricate geometries.

- Quality & durability: Rapid cross-linking yields high hardness, adhesion, chemical/abrasion resistance, and glossy, uniform films with minimal solvent entrapment.

- Sustainability benefits: UV curing systems offer significant sustainability advantages, including reduced solvent usage, less waste, lower energy consumption, and lower greenhouse gas emissions compared to traditional heat-based methods. These systems reduce the need for pollution controls and transportation, lowering environmental impact and operating costs. Learn more from RadTech, the association for UV and EB technology.

- Compact and flexible integration: Small lamp heads/tunnels and instant on/off capabilities simplify retrofits, reducing floor space compared to long thermal ovens.

- Safety note: Design curing stations with enclosures, interlocks, and shielding, provide eye/skin PPE, and manage exposure in line with established NIOSH/OSHA guidance on UV radiation.

UV vs. thermal/IR: Unlike ovens that heat air and substrate mass, UV concentrates energy in the coating itself, reducing oven footprint, utility load, and downstream pollution controls.

Together, these advantages make UV curing a faster, cleaner, and more controllable alternative to heat-based drying, particularly where line speed, film quality, and energy consumption are key considerations. When evaluating process changes, begin by mapping dose, wavelength, and film build to your specific application.

UV Curing Applications: Versatility Across Industries

UV curing systems deliver exceptional versatility for modern manufacturing. By selecting the right UV curing light wavelength, intensity, and exposure time, a single system can cure inks, paints, adhesives, and resins across diverse production environments. This approach yields fast, consistent results while avoiding the delays and defects commonly associated with heat-based drying.

UV curing lamps are utilized in numerous industrial processes where speed, precision, and performance are crucial.

- Printing & Packaging – UV-curable inks, varnishes, and overprint coatings cure instantly on paper, film, foil, plastics, and metals. This process supports vibrant colors, sharp detail, and strong adhesion on non-porous substrates for packaging, labels, and graphic arts.

- Adhesive Bonding & Assembly – UV curing adhesives deliver fast, precise bonding for electronics, optics, and medical device manufacturing. Low heat input preserves sensitive components while achieving strong, high-clarity bonds.

- Industrial Coatings & Finishes – UV curing paints and clear coats provide hardness, gloss control, and chemical/abrasion resistance on wood, flooring, plastics, metal, and glass. Inline curing systems cut work-in-process and eliminate long bake cycles.

- Medical & Pharmaceutical Packaging – Low to zero-VOC UV UV curing paint chemistries support cleanroom and environmental compliance while producing medical-grade coatings, adhesives, and printed packaging with rapid, consistent results.

- Electronics & Semiconductors – UV curing glue and adhesives protect heat-sensitive components in PCBs, conformal coatings, potting, and solder masks, enabling clean, repeatable processes without the risk of reflow.

- 3D Printing & Resin Workflows – SLA/DLP/LCD printers and post-processing stations utilize UV curing lights in the 365nm UV lamp range, which is characterized by high-intensity UV curing. 365–405 nm is the standard wavelength for solidifying photopolymer layers quickly and consistently, resulting in final parts with excellent mechanical properties.

Learn more about UV curing applications across various industries and how LightSources can meet your system requirements.

Precision UV Curing with LightSources Lamp Technologies

LightSources delivers high-performance UV curing light solutions engineered for reliability, spectral accuracy, and production uptime. With ISO 9001:2015 registration and global manufacturing expertise, we design, engineer, and manufacture UV curing lamps for OEMs and system integrators seeking repeatable results, custom configurations, and reduced lead times.

UV Curing Lamp Types and Performance Options

We offer three core UV curing lamp types, each optimized for specific process demands:

-

Medium Pressure UVA Curing Lamps (MPUV/MPHO)

These polychromatic lamps emit energy across the 200–400 nm range, supporting rapid curing of coatings, inks, and UV curing adhesives. Our MPUV lamps are engineered for high power densities, ranging from 100 to over 700 watts per inch, and arc lengths of up to 85 inches. Constructed with ultra-low water content quartz, molybdenum foil hermetic seals, and pure tungsten pin electrodes, these lamps deliver long-lasting arc stability, high output, and durability under continuous operation.

Ideal for fast through-cure in thick films and pigmented systems, high-pressure arc lamps offer powerful UVA/B output. Optional metal halide doping allows spectral tuning to match your photoinitiators. These lamps support compact system footprints and fast takt times, particularly in high-speed packaging, label printing, and adhesive curing lines.

Low-pressure curing lamps provide targeted wavelength output at 254 nm, making them ideal for applications that require precise control, low thermal load, and high energy efficiency. These lamps are well-suited for cationic ink curing, UV primers, and specialty adhesives. Output ranges from 300 to 1200 watts with lamp lengths between 1 and 2 meters. Vertical operation is supported for space-constrained environments.

Application-Specific Curing Lamp Customization

LightSources specializes in lamp and base customization for proprietary curing systems and new equipment platforms. We work closely with OEMs and designated ballast partners to develop lamp designs optimized for intensity, wavelength, arc geometry, and integration. Custom and private-label options are available for all curing lamp lines.

Engineering Support for Reliable Scale-Up

To ensure your curing process runs efficiently from pilot to full production, our engineering services include:

- Irradiance Modeling & Qualification – Dose mapping (mW/cm², mJ/cm²), edge-effect analysis, and modeling for shadow zones or complex film builds

- Optical & Thermal Stack Design – Material selection for reflectors (elliptical/parabolic), quartz types, and ozone-generating vs. ozone-free configurations

- Electrical Integration – Matched power supplies and ballasts, interlocks, dimming control, and feedback loop placement

- Fixture & Airflow Considerations – Design for thermal management, fixture stability, and mounting clearance

- Rapid Prototyping & Validation – Samples for bench testing, production simulation, and complete PPAP-style documentation

Get expert support for designing, specifying, or upgrading your UV curing system. LightSources engineers will help you align lamp output, reflector performance, and system integration with your throughput, chemistry, and quality goals. Discover our comprehensive range of customizable UV curing lamps for advanced applications. All of our UV lamps incorporate the best in proprietary technologies, such as our LongLife+™ process, which enables our UVC lamps to maintain up to 80% of their output for up to 16,000 hours.

Replacement UV Curing Lamps for Superior Quartz & Primarc Baldwin Systems

Maintain performance and uptime on legacy curing lines with drop-in replacement UV lamps, engineered to match the original electrical, spectral, and mechanical specifications. LightSources supplies high-quality equivalents to meet or exceed the product performance of lamp suppliers such as Superior Quartz and Primarc Baldwin.

Superior Quartz replacements

Superior Quartz produces widely used medium-pressure UV lamps for printing and coating lines in a range of arc lengths and watt densities. As those lamps age out, we provide like-for-like replacements matched to the original arc length, spectrum, and power so cure speed and film properties remain consistent. Where appropriate, we can match or exceed OEM performance and tailor details (e.g., quartz, electrode design) to better align with your process window or maintenance interval. Learn more: High-Quality Replacements for Superior Quartz UV Lamps.

Primarc Baldwin replacements

With Primarc Baldwin no longer manufacturing UV curing lamps in the U.S., many users need a stable source for ongoing production. LightSources builds compatible medium-pressure lamps that install without mechanical changes, cross-referenced to Primarc Baldwin specifications for arc length, watt density, and spectral profile. If desired, we can optimize lamp chemistry to improve life or challenging through-cure while preserving legacy geometry and electricals. Learn more: Replacement Solutions for Primarc Baldwin UV Curing Lamps.

UV Curing Education: FAQs, Glossary, and Downloads

Get quick, engineer-focused answers to common UV curing questions, then explore our glossary and technical downloads for a deeper understanding.

Frequently Asked Questions

How do I choose a wavelength (e.g., 365 nm vs. 395/405 nm) for my chemistry?

Match the lamp’s spectral peaks to your photoinitiator’s absorption. 365 nm UV-A often improves initiation and depth of cure for many resins/adhesives; 395/405 nm can reduce surface over-exposure and heat in some LED workflows. For blended or pigmented films, pair the spectrum with sufficient irradiance for through-cure.

What actually determines “dose,” and how do I size my lamp to hit it?

Dose = irradiance (mW/cm²) × exposure time (s) at the working plane. Specify to the worst-case location (distance, angle, shadowing), then back-calculate the required watt density and line speed. Validate with a calibrated radiometer and signed acceptance criteria (mJ/cm²).

When should I use medium-pressure UV (MPUV) instead of low-pressure UV or LED?

Use MPUV when you need a broad UV-A/UV-B spectrum, high intensity, and robust through-cure in thicker or pigmented films at high line speeds. Low-pressure/amalgam is beneficial for niche chemistries and precise dimming, while LEDs excel in surface snap, low heat, and instant on/off, often performing best in hybrid configurations.

What maintenance has the most significant impact on delivered dose?

Keep reflectors clean and in spec, maintain lamp cooling/airflow, and replace lamps at the dose-based end-of-life (not just after a certain number of hours). Verify stand-off and alignment; small geometry changes can drop irradiance at the part more than you expect.

How do we ensure the safety of operators working around high-intensity UV?

Use enclosures and interlocks, specify proper eye/skin PPE, and post access controls. Include UV curing light sensors tied to alarms, and train for lamp handling, quartz cleanliness, and hot-surface precautions.

For more medium-pressure specifics, see our MPUV FAQs.

Glossary of Terms

Need a refresher on irradiance, dose, watt density, photo initiator, or UV-A, B, and C? Browse the complete Glossary of Terms for precise definitions, formulas, and usage notes you can hand to operators and new engineers.

Technical Downloads

Access spec sheets, maintenance checklists, safety notes, reflector guidance, and dose-mapping templates in our Downloads library. Use these documents to standardize qualification (mW/cm², mJ/cm² targets), plan preventive maintenance, and train teams on best practices for lamp life and consistent cure.

Elevate Production with UV Curing Lamp Specialists

LightSources delivers engineered UV curing lamps and support that align dose, spectrum, and line speed to your material and quality targets. From application design to qualification, our team helps you achieve consistent cure, stable film properties, and dependable uptime with UV curing.

Explore our UV Curing Lamps, browse real-world UV Curing Applications, and check out our UV Curing Education hub for downloads, FAQs, and a glossary.

LightSources is a leading designer and manufacturer of high-tech UV lamps, partnering with OEMs and system integrators across industries worldwide. Our engineers bring deep technical knowledge to every solution, offering prototype development, spectrum matching, and process optimization tailored to your application. Contact us to explore advanced, patent-protected lamp technologies engineered for performance-driven UV curing.